Behind the panels: LPR Corrosion panel

- AE

- Aug 13, 2025

- 1 min read

This "Behind the panels" blog shows a LPR corrosion panel with two LPR corrosion sensors.

Corrosion measurements are used in cooling/heating circuits, industrial piping systems and drinking water applications. The Advantage Controls NANO-M units are designed to monitor the linear polarization resistance (LPR) between two metal tips. Relative corrosion & pitting rates are calculated by measuring polarization voltage and current.

These LPR corrosion sensors need a constant flow rate of 6 liters per minute. The flow must be traveling into the sensor tips. A straight 3/4" pipe of around 20 cm is needed before the tips. Advantage Europe provides the corrosion panels with the necessary components to have a good as possible measuring result.

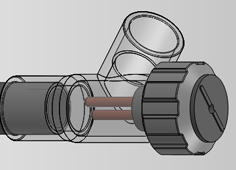

The sensor tips are provided with a quick release tee. This makes inspection/ installation easy.

A diaphragm valve and rotameter with low flow switch make it simple to control and monitor the flow rate.

Then NANO-M units measure the corrosion and pitting rate. The unit shows the values on the screen and have an alarming or setpoint relay.

All units include two 4-20mA output signals, to send out the corrosion and the pitting rate.

LPR Sensor probe tip types: